Duplex 2205 Plate Specification | ASTM A240 / ASME SA240 / NACE MR-0175 |

Tolerances of width and thickness of Duplex 2205 Plate | EN 10258 (formerly DIN 59381) EN 10151 ASTM A240 Type 2205 strips for springs EN 10088 Duplex Steel 2205 strip (general) |

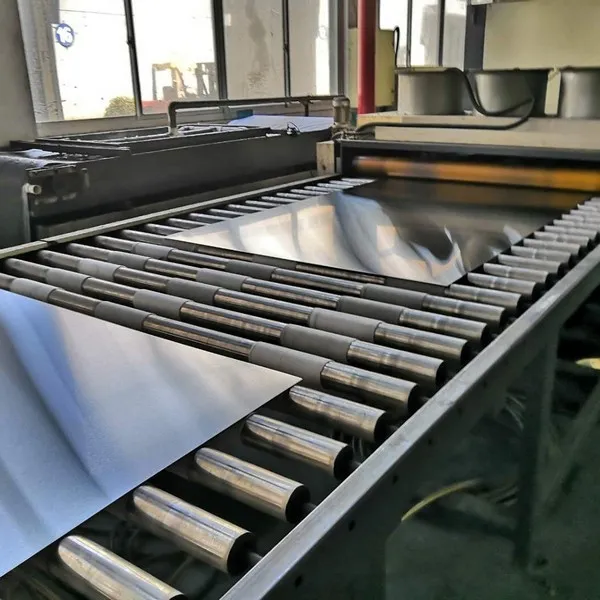

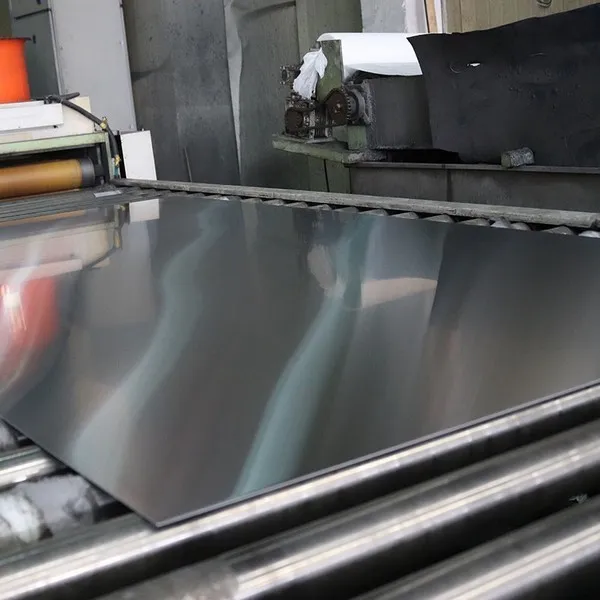

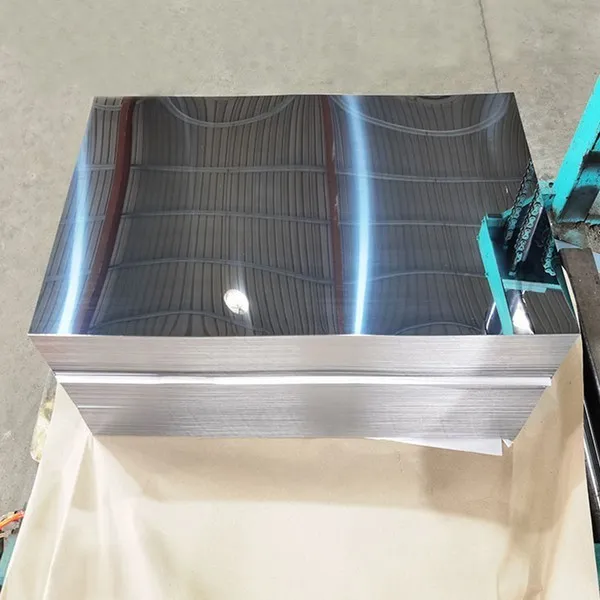

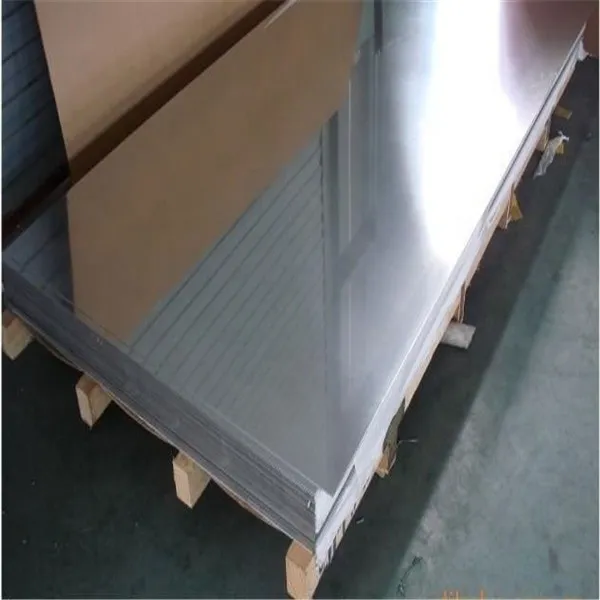

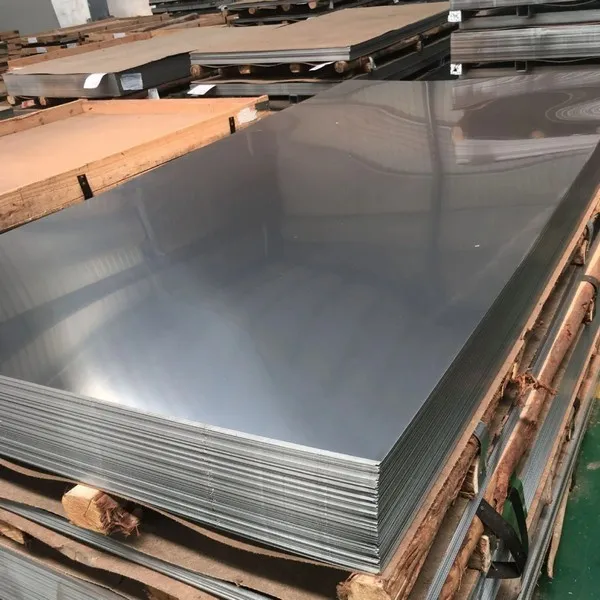

Standard Duplex 2205 Plate sizes in stock | 1000 x 2000 mm, 1220 x 2440 mm, 1500 x 3000 mm, 2000 x 2000 mm, 2000 x 4000 mm Cold rolled Duplex 2205 Plate 0.5-6.4 mm Hot rolled Duplex 2205 Plate 3.0–10.0 mm |

SA 240 TP 2205 Plate & Sheet Thickness | 0.1 to 100 mm Thk |

Width | 10-2500mm |

Duplex 2205 Stainless Steel Plate & Sheet Length | 2m, 2.44m, 3m, or as required |

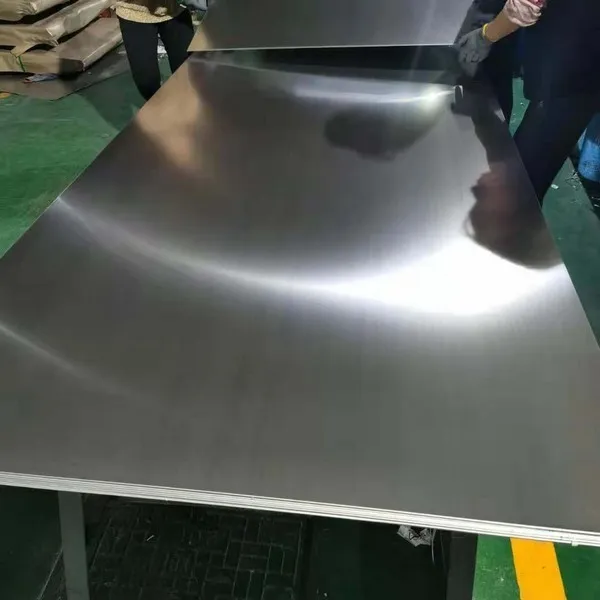

Duplex 2205 Plate Finish | 2B, 2D, BA NO(8), Cold rolled sheet (CR), Hot rolled plate (HR), SATIN (Met with Plastic Coated), No.1 finish hot rolled ASTM A240 Type 2205 Plate, 1D, 2B, No.4, BA, 8K, satin, hairline, brush, mirror etc. |

SA 240 GR 2205 Plate & Sheet Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard |

Stock available in form of | Duplex 2205 Plate, Sheet, Coils, Foils, Strip, Flats, Clad Plate, Plain Sheet, Rolling Sheet, Rolling Plate, Flat Shim, Flat Sheet, Shim Sheet, Rolls, Blank (Circle), sheared, annealed, soft annealed, descaled, tread plate, Checker Plate |

Stocking distributor of | Acroni Plate Arcelormittal Plate Outokumpu Plate Aperam Plate |

Plasma profiles | As per client's specification |

Profiling | To provide a full profiling service in UAE we use numerous profiling methods including: Laser Plate Cutting Plasma Plate Cutting Oxy-propane Flame Cutting |

Value added services for Duplex 2205 Plate | Cut-to-length Laser cutting Slitting Polishing Blanking Waterjet cutting Plasma cutting Edge preparation Welding Sawing and shearing Bending and mechanical processing |

Standards and approvals for Duplex 2205 Plate | EN ISO 18286 EN 10051 EN 10088-1 ISO 15510 EN ISO 9445 ASTM A 480 ASTM A 959 ASME IID |

Why choose us? | Large stock of Duplex 2205 Plate Mill Test Certificate is supplied with shipment. Any third party inspection is accepted. Duplex 2205 Plate are tested to ASTM A923 Method "C" or ASTM G48 Method "A". Minimum Nitrogen content and Ferrite Count Test |