High Strength Steel Plate is one such type of plate that has improved strength, formability, and weldability. They also display better resistance to atmospheric corrosion as compared to other conventional steel. High Strength Steel Plate is used due to a number of reasons. Firstly, the structural section can be reduced by increasing the strength of the steel. This in turn reduces the erection and fabrication cost.

High Strength Carbon Steel Plate can also be used to reduce the size of the structural element. This makes it possible to develop elegant and aesthetically appealing structures. These High Tensile Plates can improve their strength by adding an alloying element such as carbon and manganese. However, the drawback of these elements is that they at times worsen the fabrication properties such as weldability. Ultra High Strength Steel Plate can have a fine grain structure resulting in higher tensile strength. This issue to the heat treatment that these High Strength Steel Sheets are passed through.

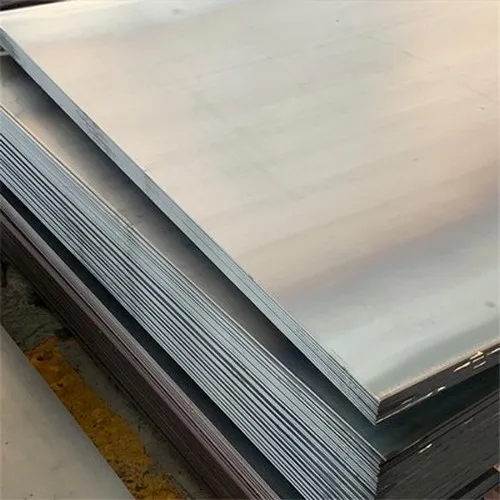

We use a conventional hot rolling method for the production of these plates. This is followed by normalizing these plates. To obtain a fine and homogenous structure of High Tensile Steel Plate this method is used. They are widely used in the production of passenger vehicles. The reason being these High Tensile Steel Sheets For Automobiles are light in weight. The best way for automobile manufacturers to enhance the performance of the machine is to reduce the weight of the product. These High Strength Hot-rolled Steel Sheets For Automobiles help in achieving this target. They are hence used in a number of automobile productions such as trains, buses, planes, and trucks.

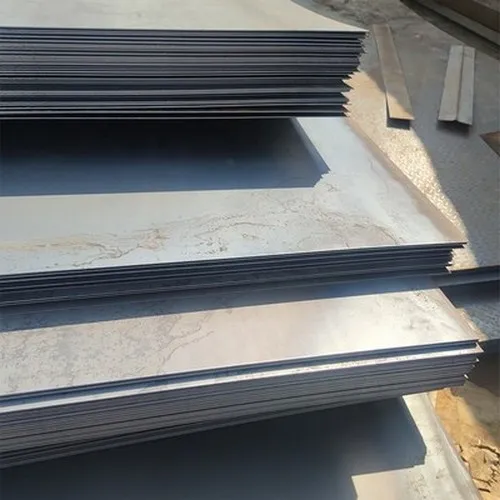

High Tensile Strength Steel Plate has an alloying content of titanium and molybdenum which makes it suitable for bending and heat treating. They are commonly used in steel frames, pipe works, and load bearing beams. High Strength Weldable Steel plates can be welded manually or using automatic modern equipment. Both these techniques give the same end results and do not hamper the property.