Call Us: +86 13370586666 interested in Contact Us? Mail us now

- Home

-

Product

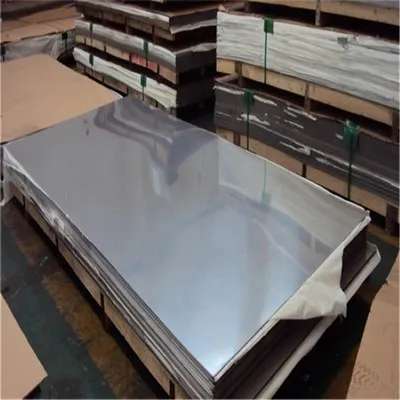

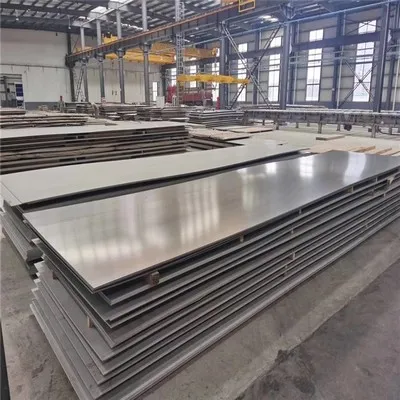

Steel PipeCarbon Steel Pipe Galvanized Steel Pipe Honing stee pipe Shaped steel pipe Stainless Steel Pipe Seamless Steel Pipe Alloy seamless steel pipe Stainless Steel Seamless Pipe Seamless Carbon Steel Pipe Spiral Steel Pipe Welded Steel Pipe Straight Seam Stee Pipe Cold Drawn Seamless Steel Tube Hydraulic Steel Pipe Boiler Steel Pipesteel plateStainless steel plate Carbon Steel Plate alloy steel plate Wear-resistant steel plate Boiler Steel Plate Shipbuilding Steel Plate Cold Rolled Steel Plate Hot Rolled Steel Plate Spring Steel weather resistant steel plate High Strength Steel Plate Pressure Vessel Steel Plate Color Coated Steel Plate/Coil

- About

- Projects

- Services

- News

- Contact